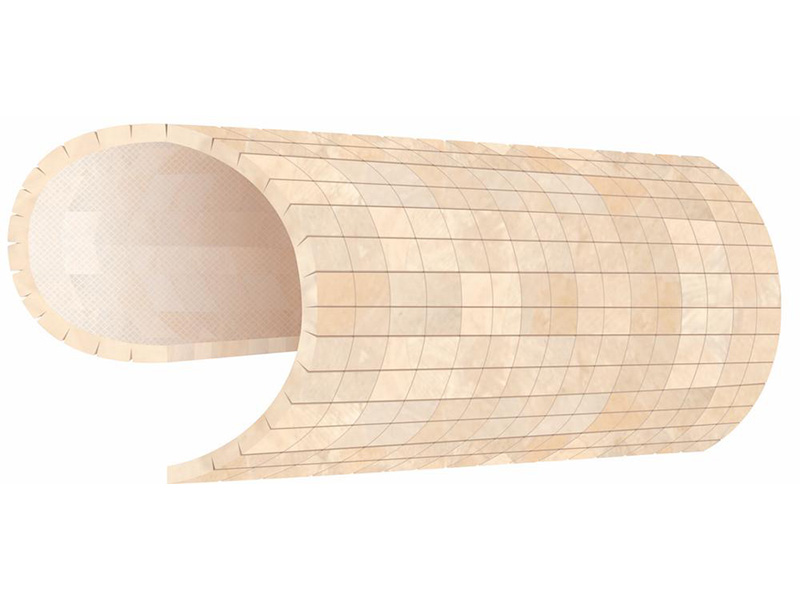

Core Materials

Composites Canada Core Materials are used for adding stiffness to composite structures without adding significant weight. From the decks of boats to skis, race cars and aircraft, the secret to light and rigid is a cored composite.

Core Materials We Carry

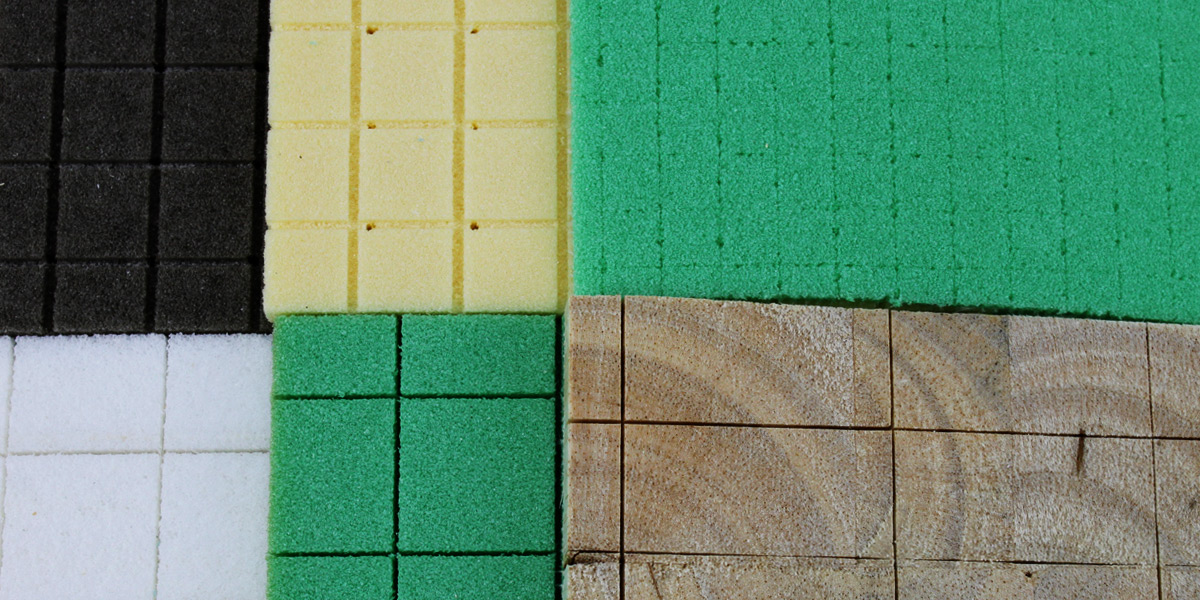

Balsa

Versatile and cost effective core material. Higher compressive strength than most other cores.

Foam

Very low densities, easy machinability, good damage tolerance – foam has the greatest variety.

Honeycomb

The highest stiffness core material with the lowest weight.

Laminate Bulkers

Flexible core material – designed to be used like a ply of fabric.