by Composites Canada | Dec 9, 2025

As we approach the end of another remarkable year, we want to extend our warmest holiday wishes to our valued customers, partners, and the entire composites community across Canada. This year has been filled with exciting projects, innovative solutions, and the...

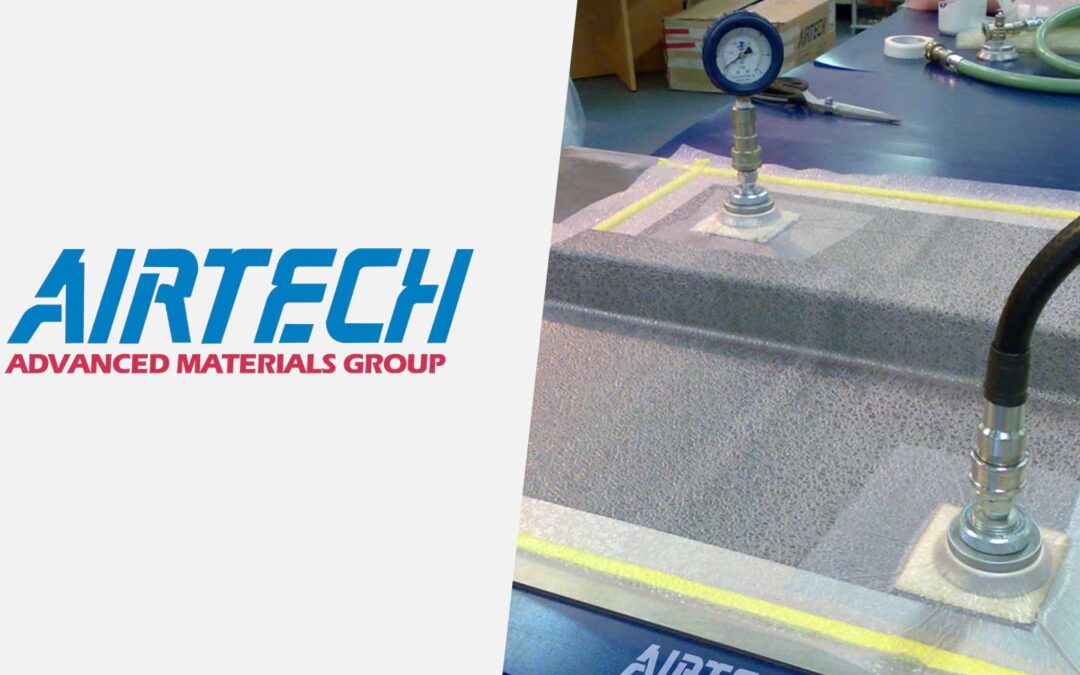

by Composites Canada | Oct 26, 2025

Composites Canada is proud partner of Airtech Advanced Materials Group, the global leader in vacuum bagging, composite tooling, and resin infusion products.With over 50 years of innovation, Airtech has set the standard in composite manufacturing. Their products are...

by Aaron Miller | Jun 11, 2025

Intro I’m going to assume, for the purposes of brevity, that we’re working with a finished, female mold, which is coated and sealed to the point of being airtight. It is easy to vacuum bag over a male mold, as well; the technique is identical. I’ll...

by Composites Canada | Mar 25, 2025

Celebrating 40 Years As Composites Canada marks 40 years, we reflect on our journey from a small fiberglass supply shop to a leading composites distributor. Founded by Mike Lukasik in 1985 as Fiberglass Factory Outlet, the company evolved through expertise,...

by Composites Canada | Aug 19, 2022

Expanding our composites knowledge, todays reading discusses Waxed and Unwaxed Resins. Waxed Resin Simplifying, imagine Waxed Resin being synonymous with Finishing Resin. Curing to a dry, non-tacky surface in 4-6 hours, Waxed Resin is intended to be used when working...

by Composites Canada | Aug 2, 2022

Everyone loves a nice shiny composite part, but what many people do not know is how to get started. In this post, we’re going to show you how our twill carbon fiber and epoxy resin starter kit can help you get that information, give you that practice, and...